Hyundai Venue: Automatic Transaxle / Repair procedures

| 1. |

Turn OFF ignition switch and disconnect the negative (-) battery cable.

|

| 2. |

Remove the air cleaner and air duct.

| (1) |

Remove the air duct (A).

|

| (2) |

Disconnect the breather hose (B) and air intake hose (C).

|

| (3) |

Remove the air cleaner assembly (D).

|

Tightening torque :

Hose clamp bolt (C):

2.9 - 4.9 N.m (0.3 - 0.5 kgf.m, 2.1 - 3.6 lb-ft)

Air cleaner assembly bolts (D) :

3.9 - 5.9 N.m (0.4 - 0.6 kgf.m, 2.9 - 4.3 Ib-ft)

|

|

|

| 3. |

Remove the battery (+) terminal (A).

|

Tightening torque :

7.8 - 9.8 N.m (0.8 - 1.0 kgf.m, 5.8 - 7.2 lb-ft)

|

|

| 4. |

Remove the battery mounting bracket (A) and the battery (B).

|

Tightening torque :

9.0 - 14.0 N.m (0.9 - 1.4 kgf.m, 6.6 - 10.3 Ib-ft)

|

|

| 5. |

Remove the ECM.

| (1) |

Disconnect the ECM connector (A).

|

| (2) |

Loosen the mounting bolts (B) and then removing the ECM bracket

assembly.

|

|

Tightening torque :

9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

|

|

| 6. |

Remove the battery tray.

| (1) |

Loosen the mounting bolt (A) and then removing the battery (+)

terminal bracket.

|

Tightening torque :

8.0 - 10.0 N.m (0.8 - 1.0 kgf.m, 5.9 - 7.4 lb-ft)

|

|

| (2) |

Loosen the bolts and then removing the battery tray (A).

|

Tightening torque :

8.8 - 13.7 N.m (0.9 - 1.4 kgf.m, 6.5 - 10.1 Ib-ft)

|

|

|

| 7. |

Disconnect the solenoid valve connector (B) and inhibitor switch connector

(A).

|

| 8. |

Separate the wiring of clip (C).

|

| 9. |

Remove the fixing clips (A) of wiring.

|

| 10. |

Loosen the bolts and nut and then removing the control cable (A).

|

Tightening torque :

(B) 14.7 - 21.6 N.m (1.5 - 2.2 kgf.m, 10.9 - 15.9 lb-ft)

(A) 9.8 - 13.7 N.m (1.0 - 1.4 kgf.m, 7.2 - 10.1 lb-ft)

|

|

| 11. |

Loosen the bolt (A) and then removing the ground line.

|

| 12. |

Separate the ATF cooler hose after removing the clamp (A).

| •

|

Carefully install the clamp not to damage the hose.

|

| •

|

Install the clamp in a correct direction not to be interfered

with other parts.

|

| •

|

After the installation, start the engine and then check

if there are any leakages from the hose.

|

|

|

| 13. |

Assemble the engine support fixture (Beam No. : 09200-38001 or 09200-3N000,

supporter No. : 09200-2S000).

|

| 14. |

Using the engine support fixture (A), hold the engine and transaxle

assembly safely.

|

| 15. |

Loosen the automatic transaxle upper mounting bolts (A) and the starter

mounting bolts (B).

|

Tightening torque :

(A) 42.2 - 54.0 N.m (4.3 - 5.5 kgf.m, 31.1 - 39.8 lb-ft)

(B) 49.0 - 63.7 N.m (5.0 - 6.5 kgf.m, 36.2 - 47.0 lb-ft)

|

|

| 16. |

Remove the dust cover (A).

|

| 17. |

Loosen the automatic transaxle support bracket mounting bolts (A).

|

Tightening torque :

88.3 - 107.9 N.m (9.0 - 11.0 kgf.m, 65.1 - 79.8 lb-ft)

|

|

| 18. |

Loosen the bolts and then removing the automatic transaxle support bracket

(A).

|

Tightening torque :

58.8 - 78.5 N.m (6.0 - 8.0 kgf.m, 43.4 - 57.9 lb-ft)

|

|

| 19. |

Lift the vehicle with a jack.

|

| 20. |

Remove the under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

|

| 21. |

Remove the drive shaft assembly.

(Refer to Driveshaft and Axle - "Front Driveshaft")

|

| 22. |

Loosen the bolts (A, B) and then removing the roll rod bracket (C).

|

Tightening torque :

(A) : 107.9 - 127.5 N.m (11.0 - 13.0 kgf.m, 79.6 - 94.0 lb-ft)

(B) : 49.0 - 63.7 N.m (5.0 - 6.5 kgf.m, 36.2 - 47.0 lb-ft)

|

|

| 23. |

Loosen the bolts and then removing the roll road support bracket (A).

|

Tightening torque :

49.0 - 68.6 N.m (5.0 - 7.0 kgf.m, 36.2 - 50.6 lb-ft)

|

|

| 24. |

Loosen the bolts and then removing the exhaust manifold stay (A).

|

| 25. |

Remove the dust cover (A).

|

| 26. |

Loosen the torque converter mounting bolts (A) with rotating the crankshaft.

|

Tightening torque :

45.1 - 52.0 N.m (4.6 - 5.3 kgf.m, 33.3 - 38.3 lb-ft)

|

|

| 27. |

Remove the automatic transaxle with a jack after loosening the mounting

bolts (A, B).

|

Tightening torque :

(A) 42.2 - 48.1 N.m (4.3 - 4.9 kgf.m, 31.1 - 35.4 lb-ft)

(B) 42.2 - 53.9 N.m (4.3 - 5.5 kgf.m, 31.1 - 39.8 lb-ft)

|

|

| 1. |

To install, reverse the removal procedure.

| 1) |

Before reassembling the automatic transaxle to the engine

assembly, make sure that there is no gap (A) between

automatic transaxle and engine assembly as below illustration.

Do not reassemble the automatic transaxle to the engine

assembly when this gap (A) exist.

|

| 2) |

While there is a gap, It would be meaning that the key

of oil pump gear is not assembled properly to the torque

converter hub. In this case, remove the automatic transaxle

assembly and then reinstall the torque converter to

automatic transaxle assembly according to the key shape

of oil pump gear.

[Correct Assembly (A) - Oil Pump Key Part (B) Engaged

Properly]

[Incorrect Assembly (C) - Torque Converter Protruded

due to Interference with the Oil Pump Key Part (D)]

|

| 3) |

If the mounting bolt is tightened forcibly in spite

of a gap, key of oil pump gear will be damaged or broken.

In this case, replace the automatic transaxle assembly.

|

|

|

Follow the separted each procedure as below according to reinstallation

or replacing with a new automatic transaxle.

|

|

| 2. |

In case of the reinstallation.

| (1) |

Replace the oil seal with a new one when ATF leak occurred because

of differential oil seal damage.

|

When installing the new oil seal, use the special service

tool(SST No.:09452-26100, 09231-H1100).

|

|

| (2) |

Check the ATF level after refilling the automatic transaxle

with fluid.

(Refer to Automatic Transaxle Syatem - "Automatic Transaxle

Fluid (ATF)")

|

| (3) |

Clear the diagnostic trouble codes (DTC) using the diagnostic

tool.

|

Even though disconnecting the battery negative terminal,

the DTCs will not be cleared. So, be sure to clear the

DTCs using the diagnostic tool..

|

|

|

| 3. |

In case of the replacing with a new automatic transaxle.

|

New automatic transaxle is already filled with specified quantity

ATF.

For that reason, it does not necessary to refill and check the

ATF but the remaining ATF inside of ATF cooler have to be removed.

|

| (1) |

Set the air blow gun in front of the ATF cooler hose (A).

|

| (2) |

Set the cup in front of the ATF cooler hose (B).

|

| (3) |

Remove the remaining ATF by blowing air into ATF cooler hose

(A).

|

| (4) |

Install the ATF cooler hose (A) and (B).

|

| (5) |

Clear the diagnostic trouble codes (DTC) using the diagnostic

tool.

|

Even though disconnecting the battery negative terminal,

the DTCs will not be cleared. So, be sure to clear the

DTCs using the diagnostic tool.

|

|

| (6) |

Reset the automatic transaxle adaptive values using the diagnostic

tool.

|

| (7) |

Perform the oil pressure characteristics input procedure.

• Oil pressure characteristics(bar code) location

• Oil-pressure characteristics input

(Automatic transaxle exchange)

|

| (8) |

Perform the TCM adaptive values learning procedure.

(Refer to Automatic Transaxle Control System - "Repair procedures")

|

|

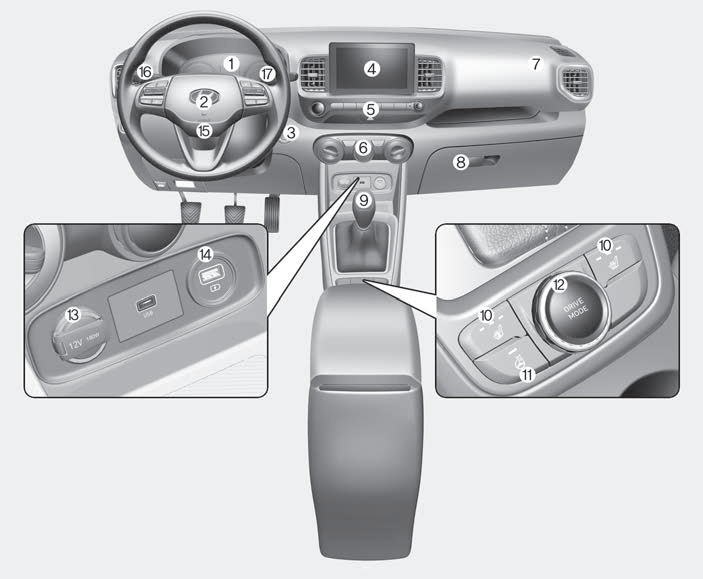

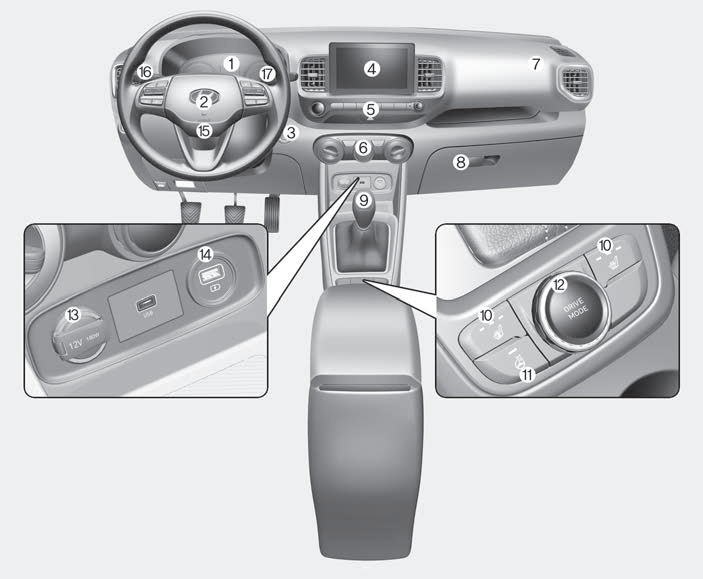

Components Location(1)

1. Automatic transaxle assembly

2. ATF cooler tube

3. Ground line

4. Shift cable mounting bracket

5...

Components Location

1. Automatic transaxle

2. Drain plug gasket

3. Drain plug

4. ATF level check plug

5. ATF level check plug gasket

6...

Other information:

Removal

1.

Turn the ignition switch OFF and disconnect the battery negative (-)

terminal.

2.

Remove the air cleaner assembly.

(Refer to Engine Mechanical System - "Air Cleaner")

3...

Inspection

1.

Disconnect the negative battery terminal.

2.

Remove the roof trim assembly.

(Refer to Body - "Roof Trim Assembly")

3.

Ground the terminals as below table, and check that the sunroof unit

operates after disconnecting the sunroof motor connector...

Categories

1. Instrument cluster

2. Horn

3. Key ignition switch/ Engine Start/Stop button

4. Infotainment system

5. Hazard warning flasher switch

read more

Components and components location

Components and components location Automatic Transaxle Fluid (ATF). Components and components location

Automatic Transaxle Fluid (ATF). Components and components location